Welding and Fabrication Services

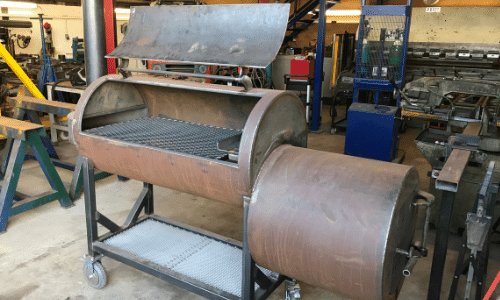

At REC Welding and Fabrication we offer a huge range of high-quality TIG, MIG & ARC welding and fabrication services from our workshop in Billingshurst, Horsham, West Sussex. We have over 20 years of industry knowledge and offer bespoke and specialist metal welding and fabrication services from small precision components to large industrial fabrications. We specialise in working with mild steel, stainless steel and aluminium.

Metal Fabricators

Our hands on experience and high-quality specialist equipment mean that our skilled welders can provide professional, precision-made products for your individual needs whatever your industry. Contact us today to discuss your welding and fabrication requirements.

What types of welding do we do?

At REC Welding, our welding and fabrication experts provide ARC welding, MIG welding and TIG welding services - this includes welding stainless steel. Our welders can perform spot welding and other welding techniques to meet your criteria. We work with mild steel, steel and aluminium.

We understand that no two jobs are the same and different requirements need special and detailed approaches. Our expert team are on hand and love new challenges, so don't hesitate to get in touch to discuss your welding requirements.

MIG welding

MIG welding is one of many techniques that utilises electricity to melt and join metals. It is a popular method of welding because of its ease of use and the speed of its welding. This is perfect for joining metals of a different thickness and a strong and smooth weld is relatively easy to achieve. Welding can be done at many different angles which means your product can be welded sturdily at all necessary points.

ARC welding

ARC welding uses an electric arc to create heat to melt and join metals. When an arc is struck between the electrode and the work piece, both the rod and work piece surface melt to form a weld pool. Simultaneous melting of the flux coating on the rod will form gas and slag which protects the weld pool from the surrounding atmosphere. Using a welding machine using either AC (Alternating) or DC (Direct) currents. Arc welding is often used to join materials including pipe and metal plate.

Our specialities

At REC Welding, we work on a case by case basis and love new and exciting projects. We work from your CAD designs or drawings to bring your vision to life.

We specialise in constructing new metalwork for the hospitality industry. We can create bespoke metalwork for bars, restaurants and venues as well as for pop up events and food trucks etc. Some of the products we have made include bar backs, racking systems, shelving and barriers and railings as well as decorative metalwork. If you would like custom design metalwork for your premises then get in touch with our expert team today.

Our capabilities span a diverse range of industries and we can cater for medium and large job loads. Our welders and fabrication team can construct bespoke railings, gates and frameworks as well as furniture frames and staircases.

We also construct metal beams for homes and the construction industry. If your requirement is domestic or commercial we have the tools and materials for the job.

Our Machinery

We have an extensive range of tools and machinery for the fabrication, bending, joining and finishing of metals. We work with a range of materials including sheet metals, steel, mild steel and aluminium.

Engineering and manufacturing metal products takes specialist machinery that needs to be operated with expertise and skill, our in house metal fabricators have over 20 years of experience meaning that you are getting top quality products from a professional working environment. Safety is paramount and with our industry experience and our professional workshop, our welders and engineers have the tools to get the job done.

Some of our Machinery includes:

- 2.5 meter press brake

- 2.5 meter guillotine

- Sheet metal roller

- Roll bending machine

- Pillar drill

- Magnetic drill

- Horizontal bandsaw

We also have a Boxford lathe, Bridgeport milling machine, a 2 ton gantry crane and a 2 ton forklift.

Contact Us Today

Talk to us about your requirements now, we aim to respond within 24 hours.